The finish is what makes the glove unique.

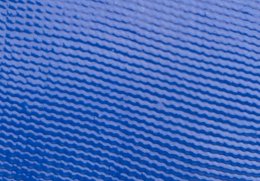

Solid Nitrile

Solid dip resists penetration of liquids and has an excellent dry grip.

Sand Grit Nitrile/Latex

The Sand Finish dip has a higher grip rating, better wear resistance and more protection than solid or foam dipped gloves.

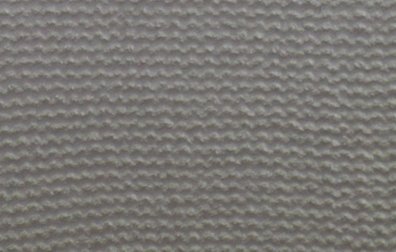

Micro-foam Nitrile

It uses a chemical to create small holes in the surface, making it smoother and more breathable. Widely used in construction, industry, agriculture, general assembly, electronics and gardening.

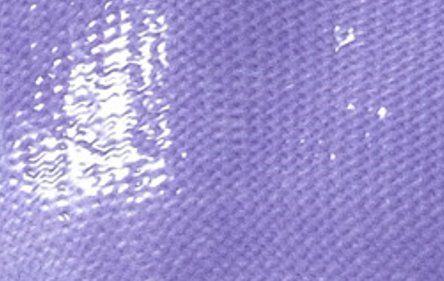

Foam Nitrile & Water-based Polyurethane

New technology provides extreme grip. Its elasticity makes the gloves long-lasting and comfortable although it is less resistant to abrasion than the solid finish.

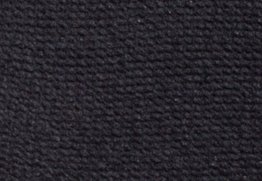

Nitrile Dots

Dotted gloves provide an extra level of grip and extra abrasion resistance when compared to standard dipped gloves, ensuring a better user experience.

Crinkle Latex

The grip factor of crinkle latex gloves is not reduced by either wet or cold conditions.

Air-Bubbled Foam Latex

While the wear resistance of air-bubbled foam may not be as high as other finish types, it offers enhanced dexterity and outstanding grip in wet/oily situations.

Polyurethane

When compared to other coating, PU offers good touch, breathable and flexible.

Silicone Technology

Technology provides a superior gripping power and great abrasion, no finger-prints making it a great choice for glass industries.